- World premiere: unveiling of the new MetalCoat 484 for high-end coating and process automation

- Solutions for offset and digital printing, coating, drying, and air purification demonstrate comprehensive system expertise

- Presentation of innovative highlights such as hydrogen-capable drying systems and the MetJET digital printing series

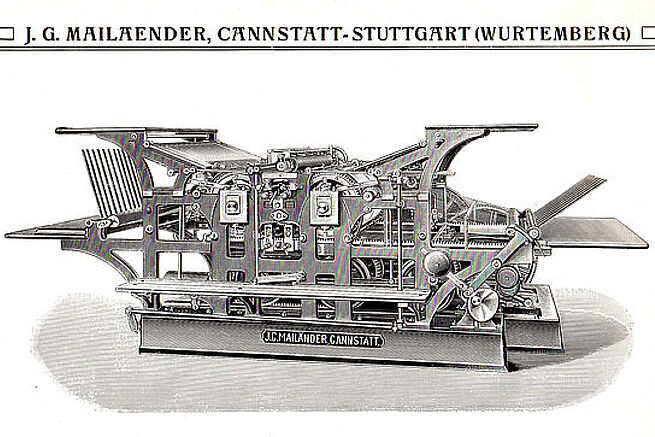

- 150 years of excellence: celebrating the jubilee of J.G. Mailänder (est. 1876)

Under the banner of holistic system excellence, Koenig & Bauer MetalPrint will arrive at METPACK 2026 in Essen (05–08 May) to present its most powerful lineup to date. As the industry’s leading system supplier, the company will showcase its unique ability to cover the entire process chain of metal decorating. Visitors to Stand 3B39 in Hall 3 can experience firsthand how Koenig & Bauer MetalPrint is redefining efficiency, digitalisation, and sustainability in the metal packaging sector.

A world premiere: The MetalCoat 484

The centerpiece of this year’s presentation is the world premiere of the MetalCoat 484. Unique features such as the automatic washing system and closed loop coating thickness control enable users to improve overall efficiency and increase profitability. By integrating the MetalCoat 484 into the production line, users benefit from reduced setup times and a significant increase in overall equipment effectiveness (OEE).

“We print it. We coat it. We cure it.”

Koenig & Bauer MetalPrint underscores its position as a ‘One-Stop-Shop’ with a portfolio that addresses every step of the metal decorating journey:

- Printing: Alongside the high-performance MetalStar 4, which remains the gold standard for high-end metal printing, the company offers the Mailänder printing machine for rough jobs. For those seeking maximum flexibility for small batches, the MetJET series offers a complete industrial digital printing solution.

- Coating: Building on the legendary heritage of Mailänder, the new MetalCoat 484 demonstrates the company’s ongoing evolution in precision coating.

- Curing: Addressing the global energy transition, Koenig & Bauer MetalPrint offers a range of drying technologies. This includes conventional gas-fired thermal drying with integrated air purification with HighEcon systems for gas savings of up to 70 per cent compared with older installations, state-of-the-art UV and UV-LED solutions, and the latest hydrogen-ready oven technology, enabling carbon-neutral production.

150 years of innovation: The Mailänder jubilee

METPACK 2026 is not only a testament to the company's innovative spirit, but also marks a historic milestone. The roots of Koenig & Bauer MetalPrint lie in three industry giants: Mailänder, LTG, and Bauer + Kunzi. This year, the company celebrates the 150th anniversary of J.G. Mailänder, founded in 1876. By laying the foundation for “Metal Printing made in Germany,” Mailänder’s spirit of innovation continues to drive the company’s modern technological breakthroughs.

A global gathering for the “metal family”

For Ralf Hipp, CEO of Koenig & Bauer MetalPrint, the trade fair is about more than just machinery: “METPACK is a family gathering for us. We are looking forward to meeting our partners and customers from all over the world face-to-face in one place. We are there to present our innovative strength and customised services that help our customers stay competitive in a changing market. We are ready for METPACK 2026.”

The Koenig & Bauer MetalPrint stand will serve as a central hub for experts to discuss the latest industry trends – such as material consumption reduction and energy efficiency – and to develop bespoke solutions for individual production requirements.