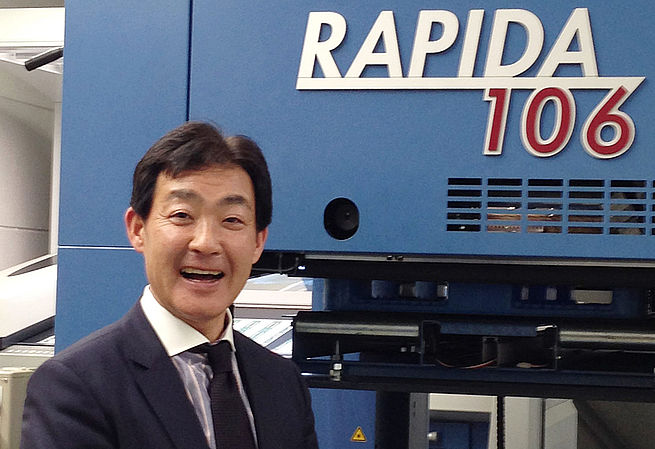

Managing director Daisuke Iwakura, the third generation of the founding family, has learned to value the benefits delivered by his high-performance Rapida 106 in the meantime. It replaced two older presses and offers additional capacity. The drastic reduction in makeready time, less start-up waste and the considerable increase in output have significantly improved print production economy. Iwakura has now become a key advocator of KBA press technology in Japan. Many other printing companies there have carried out tests on the Rapida 106 before making investment decisions.

Equipped with DriveTronic SPC, DriveTronic Plate Ident, CleanTronic washing systems, DriveTronic SFC coater with AniloxLoader and kit for mixed operation with conventional and UV inks the Rapida 106 features everything offered by today’s cutting-edge sheetfed offset. Daisuke Iwakura is convinced that the press will pay off much quicker than planned even though he thought the numbers presented by KBA in the beginning were too optimistic.

A few weeks ago Daisuke Iwakura found out about the latest trends in UV technology from KBA-Sheetfed Solutions in Radebeul for future investments. Planning investments together with KBA is a lot easier for him with the knowledge that the performance data presented by KBA are correct. This trust was confirmed once again with a series of recent print tests. This is also true of many other Rapida users in the land of the rising sun. Three years after installing the first Rapida in Japan 40 per cent of first users have ordered a further press from KBA.