- Leading print and post-press manufacturer

- Insights into the future of folding carton production

- Solutions beyond traditional press engineering

© Koenig & Bauer

Koenig & Bauer, the leading manufacturer of sheetfed offset presses for folding carton printing, invited existing and prospective customers from all over the world to an exclusive event under the banner ‘Post-press Solutions Experience’ that was held from 19 to 22 November. More than 150 guests from twelve countries were given the opportunity to learn more about the latest solutions for even greater profitability and efficiency at the post-press stages of folding carton production.

© Koenig & Bauer

The objective of the event was to present innovations in the field of post-press technology and to share comprehensive insights into the future of folding carton production. It addressed both potential customers and current users who wish to further optimise their production processes and are therefore interested in learning about the latest trends in the industry.

End-to-end process chain for folding carton production

Having expanded its expertise in folding carton printing to cover the entire value chain of post-press technologies, Koenig & Bauer is able to offer its customers solutions that go beyond traditional press engineering, such as 360-degree workflow solutions. As a trusted advisor, Koenig & Bauer supports its customers at all stages of folding carton production and presents alternatives to established products in the field of post-press. The combination of leading-edge press engineering and innovative post-press solutions enables users to stand out in an increasingly competitive market and to develop new business opportunities.

© Koenig & Bauer

What’s more, Koenig & Bauer is a champion of digital networking and offers a manufacturer-independent ecosystem in the form of myKyana that optimises the complete production process and promotes seamless communication between machines. This digital platform ensures that all machines and processes communicate efficiently with each other – a key prerequisite for successfully mastering the ever-higher demands of customers and markets.

© Koenig & Bauer

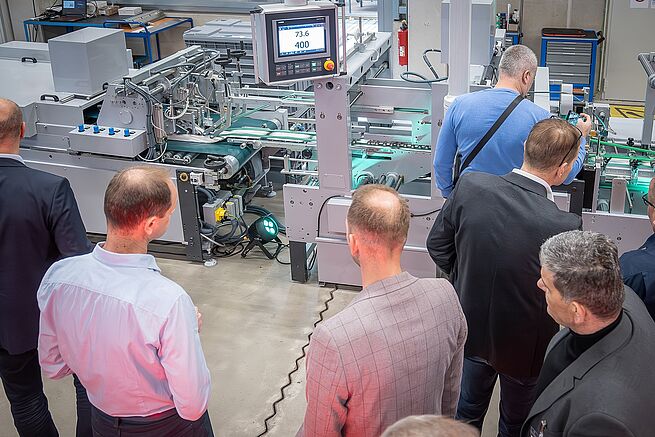

Live: practice-oriented presentations and machine demonstrations

A highly varied agenda allowed the international post-press experts to gather a wealth of information on current and future developments in folding carton production.

© Koenig & Bauer

Ralf Sammeck, member of the executive board of Koenig & Bauer and CEO of Koenig & Bauer Sheetfed, used his keynote presentation to explain the post-press strategy and digital orientation of the company. He positioned Koenig & Bauer as a leading partner in the field of folding carton production. Subsequent breakout sessions offered the participants additional, more detailed information on topics such as the service experience, performance management and expanding post-press options.

© Koenig & Bauer

Practical demonstrations with live production runs and job changeovers presented a broad spectrum of innovative solutions with which Koenig & Bauer is shaping a forward-thinking and efficient future for folding carton production. The demonstrations covered the following machines and solutions in the Radebeul Customer Experience Centre:

- CutPRO Q 106 SB – the performance benchmark in flat-bed die-cutting for maximum outputs in industrial folding carton production

- CutPRO X 106 – the innovative and customer-tailored rotary die-cutter for future-oriented in-house production

- Ipress 106 PRO SB – the new generation of the proven Ipress 106 flat-bed die-cutter family for even more efficiency

- Omega Allpro 110 – the folder-gluer for complex packaging applications and high productivity

- myKyana – the digital ecosystem from Koenig & Bauer

Customers from different regions reported on their business development successes using sheetfed offset and post-press technologies from Koenig & Bauer. Thanks to innovative solutions geared to diversification and differentiation, they are in a better position to respond to the constantly changing demands of their customers. Koenig & Bauer offers not only the machines, but also tailored solutions covering the entire value chain of folding carton production.

© Koenig & Bauer