- Investment in a Rapida 106 press and an Omega Alius 90 folder gluer

- Unique new production line custom-designed for competitive advantage ahead of new regulations

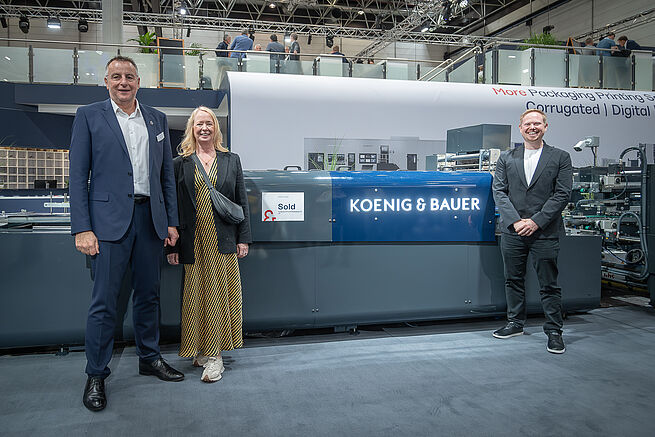

Fresh from the manufacturing line at Koenig & Bauer Duran, a new Omega Alius 90 folder gluer at drupa is on the first leg of its journey to a new home in Leicester, UK. Along with a brand new Rapida 106 press, the Omega Alius 90 folder gluer is part of a major investment with Koenig & Bauer by Qualvis Print & Packaging and is showcasing as a post-press draw on the stand in Hall 16.

Qualvis already operates a seven-colour Rapida 106 with twin coaters and an Iberica cutter creaser. However, the new configuration has been described as something “entirely different”. It will meet a very real need in the market, according to insiders, but will remain undisclosed for competitive advantage.

“All I can reveal about the new press is that it is quite unique. Our product designers have worked closely with Qualvis, under strict non-disclosure, to develop a one-of-its-kind capability that will give Qualvis a jump on the market,” says Chris Scully, Managing Director of Koenig & Bauer UK.

A statement from the joint managing directors of Qualvis, Lisa Smith and Marcus Short, comments “We're very excited to be installing a unique Koenig & Bauer press configuration, it has been a true collaboration to get to this point and we can't wait to showcase our new offering. Koenig & Bauer truly aligns with our ethos of innovation and is looking to push the market forward in both sustainability and printing effects. Watch this space!”

“Not only have we partnered with K&B for our new press but we'll also be installing the new Omega Alius 90 folder gluer coming direct from drupa. The first of the new model to market will offer high speeds and intelligent automatic setup. This new folder gluer complements our requirements perfectly. These purchases complement the recent investment strategy started two years ago, that includes not only machines, but technology and a solar energy investment to further reduce our carbon footprint. This completes phase 2 of our long-term investment programme and allows us to continue to focus on sustainable cutting-edge innovation and first-to-market solutions, which is our passion, whilst increasing capacity to allow for growth which has been exponential over recent years. Extremely exciting times.”

No stranger to major investment, Qualvis prides itself on using high-end technology for the good of its workforce as well as for productivity. The company’s focus on offering sustainable production to customers and brands has been a significant driver in recent spending, and it is understood that this latest deal is no exception.

The Rapida 106 offers a wide range of features to boost efficiency and benefit sustainability efforts through reduced waste and energy consumption. These include automatic simultaneous plate changing and closed-loop inline measurement of ink densities and registration. By recirculating unsaturated air, VariDry Blue 2 technology can also save up to 30 percent energy in the dryer. Similarly, this latest Omega Alius features full servo control, intelligent automatic setup with calculation from carton drawing, and high-speed throughput of up to 600 m/min.

“Qualvis make it very easy for customers to do the right thing in terms of sustainable packaging. From organic vegetable inks to board supply and recycled and recyclable plant-based materials, their whole packaging production is vegan friendly,” adds Scully. “At Koenig & Bauer, one of our main strengths is our ability to innovate and develop technology on a project-by-project basis. We’re very pleased that they chose us to be their innovation partner on this project. I personally can’t wait to see where they take this.”