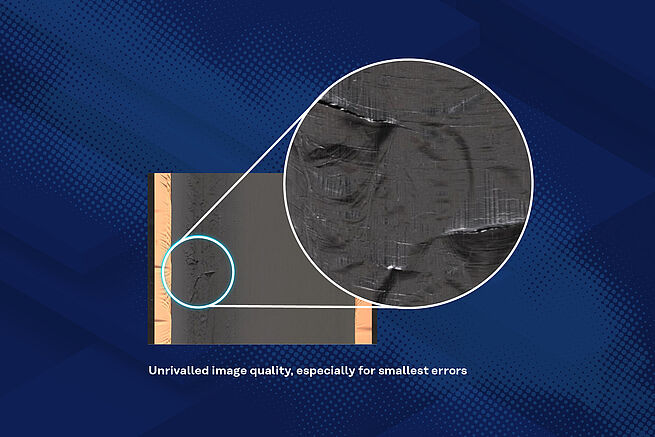

- Innovative solution for the in-line inspection of battery foils and other metallic, paper and foil-like web products

- Guarantees the highest quality standards in ongoing production

© Koenig & Bauer

From October 8th to 10th, Mitsubishi Electric, a strategic partner of Koenig & Bauer, will present the jointly developed inspection module Qi<+>PRO to the world public for the first time at its exhibition stand at VISION in Stuttgart. The Qi<+>PRO module is an innovative solution for the in-line inspection of battery foils and other metallic, paper and foil-like web products that are difficult to inspect with conventional camera systems.

© Koenig & Bauer

The module contains a highly developed image acquisition system including mechanics and has standard interfaces for electrics, mechanics and data exchange. This means that it can be integrated into almost any production environment via plug-and-play. The demonstration shows the surface inspection of an electrode foil after the coating process as well as the inspection of a printed substrate.

© Koenig & Bauer

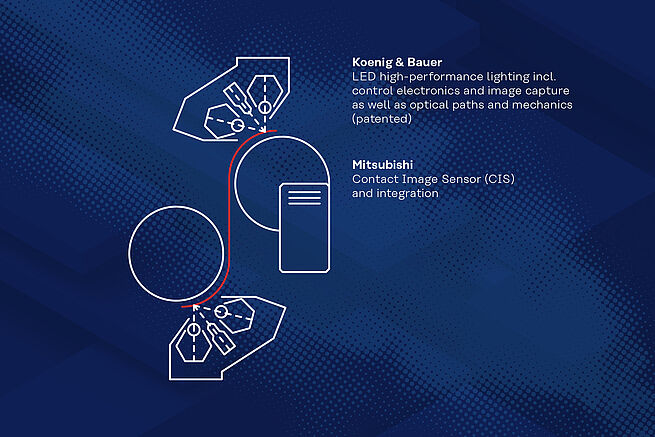

The central elements of this module are Koenig & Bauer's own inspection module including LED high-performance lighting and the Mitsubishi Contact Image Sensor (CIS).

The combination of high-resolution image capture, high-performance image processing and connection to the production system guarantees the highest quality standards in ongoing production.