- Demo of first working prototype of Koenig & Bauer Analytics showcased at Hannover Messe 2023

- Partnering with Google as number 1 cloud provider for industry solutions to become one-stop systems supplier

- Goal of near 100 per cent productivity for as many machines as possible

As a leading manufacturer of the printing industry, Koenig & Bauer deals with vast amounts of valuable data every day. It doesn’t come as a surprise that when choosing an innovative partner for the management and processing of this data, the group opted for Google Cloud. With their strong manufacturing focus and dedicated industry solutions, the cloud provider will be a key ingredient to getting the print and packaging world ready for the future.

A demonstration of the first working prototype (MVP) of the new product Koenig & Bauer Analytics was showcased at the Google Cloud booth at Hannover Messe this week. This new product is developed as a powerful analytics tool which seamlessly combines data from different sources, such as machine log files and data from existing MES and MIS systems. It lets users create complex evaluations in the most simple way, which enables them to gain a holistic understanding of their production processes.

Transforming from a manufacturer to a digitally savvy technology company

Numerous representatives from leading companies in the manufacturing industry visited the Google Cloud booth and were able to experience the Koenig & Bauer Analytics prototype – which was born out of Koenig & Bauer’s digital innovation hotbed – first hand. A lively exchange of best practices took place during these visits.

At just one year old, the Koenig & Bauer digital unit has taken up the challenge of transforming the print and packaging world into a digitally savvy tech-based space. At the centre of this journey lies an IIoT (Industrial Internet of Things) strategy. This data-driven and customer-centric approach is utilising advanced data analytics, artificial intelligence and machine learning in ways that have never been applied to the printing industry.

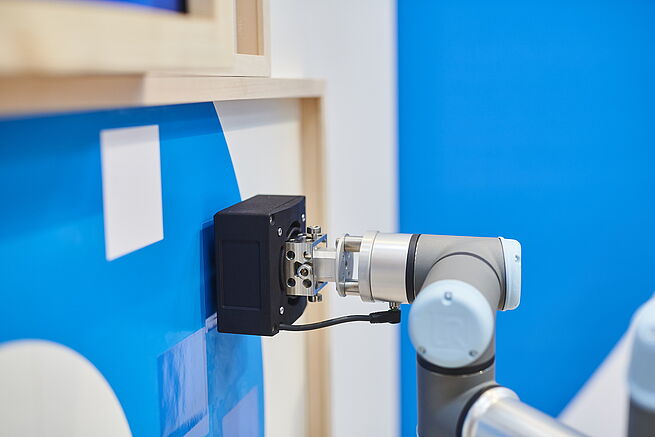

This notion is also perfectly mirrored in Koenig & Bauer’s exhibition at Hannover Messe 2023. But as we know, software rarely catches the eye of trade show visitors by itself. And what could be more fitting for the leading industrial trade fair than interaction with a robot? Featured in the booth is Koenig & Bauer’s 4PL Cobot, a print and apply system demonstrating Koenig & Bauer’s impressive automation capabilities throughout the entire print production process. The collaborative robot is able to print and apply labels at any position on a product or pallet and visually verify them. With its trade show appearance, Koenig & Bauer marries print with the world of digitalisation and automation. From small labelling systems such as the 4PL to large printing presses – Google Cloud technology enables them to process data from all machines – big or small – and develop new products and business models for their clients.

Exceeding print: close to 100 per cent productivity based on intelligent data processing

Partnering with one of the world’s leading AI specialists and number 1 cloud provider for manufacturing solutions laid the groundwork to becoming a one-stop systems supplier for their customers. The MVP presented at the Hannover Messe this week will grow to enable Koenig & Bauer’s clients to identify patterns, trends, and anomalies in production processes, and take action before issues escalate into major problems.

The goal is for as many machines as possible to approach almost 100 per cent productivity. Central to this is Google Cloud’s Manufacturing Data Engine (MDE) which allows for consolidation of data silos and extraction of insights from manufacturing data to improve efficiency and productivity.

The official product release is planned for fall 2023.